- Home

-

About

AboutDongguan Leynow Mechanical and Electrical Technology Co., Ltd. is the most professional manufacturer in the field of vacuum pumps and compressors. It is a high-tech enterprise that develops and manufactures vacuum pumps. It has more than 10 years of technology research and development experience and provides customers with the most complete vacuum solutions. Welcome to call:4006-112-722。

- Consulting service hotline

- 4006 112 722

-

Official Account

Official Account WeChat Business

WeChat Business

-

News

NewsDongguan Leynow Mechanical and Electrical Technology Co., Ltd. is the most professional manufacturer in the field of vacuum pumps and compressors. It is a high-tech enterprise that develops and manufactures vacuum pumps. It has more than 10 years of technology research and development experience and provides customers with the most complete vacuum solutions. Welcome to call:4006-112-722。

- Consulting service hotline

- 4006 112 722

-

Official Account

Official Account WeChat Business

WeChat Business

-

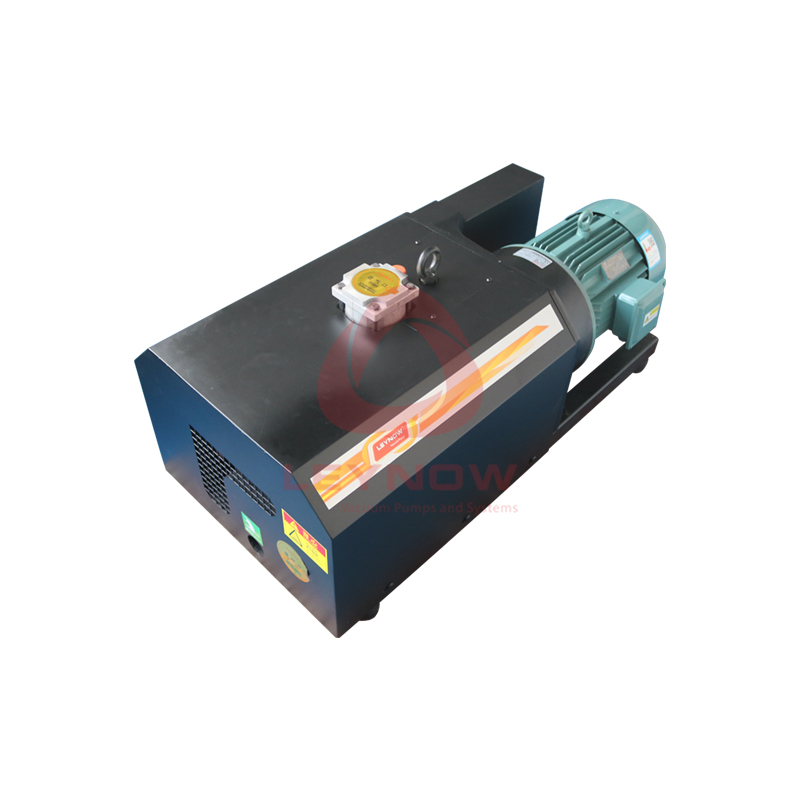

Product

ProductDongguan Leynow Mechanical and Electrical Technology Co., Ltd. is the most professional manufacturer in the field of vacuum pumps and compressors. It is a high-tech enterprise that develops and manufactures vacuum pumps. It has more than 10 years of technology research and development experience and provides customers with the most complete vacuum solutions. Welcome to call:4006-112-722。

- Consulting service hotline

- 4006 112 722

-

Official Account

Official Account WeChat Business

WeChat Business

-

Applications

ApplicationsDongguan Leynow Mechanical and Electrical Technology Co., Ltd. is the most professional manufacturer in the field of vacuum pumps and compressors. It is a high-tech enterprise that develops and manufactures vacuum pumps. It has more than 10 years of technology research and development experience and provides customers with the most complete vacuum solutions. Welcome to call:4006-112-722。

- Consulting service hotline

- 4006 112 722

-

Official Account

Official Account WeChat Business

WeChat Business

-

Service

ServiceDongguan Leynow Mechanical and Electrical Technology Co., Ltd. is the most professional manufacturer in the field of vacuum pumps and compressors. It is a high-tech enterprise that develops and manufactures vacuum pumps. It has more than 10 years of technology research and development experience and provides customers with the most complete vacuum solutions. Welcome to call:4006-112-722。

- Consulting service hotline

- 4006 112 722

-

Official Account

Official Account WeChat Business

WeChat Business

- Contact

CHN

CHN