Electronics are part of modern daily life and imagining life without them is no longer possible. Computers, smartphones, automobiles, home control devices, medical equipment and other highly integrated circuits are all based on semiconductor technology.

Advantages

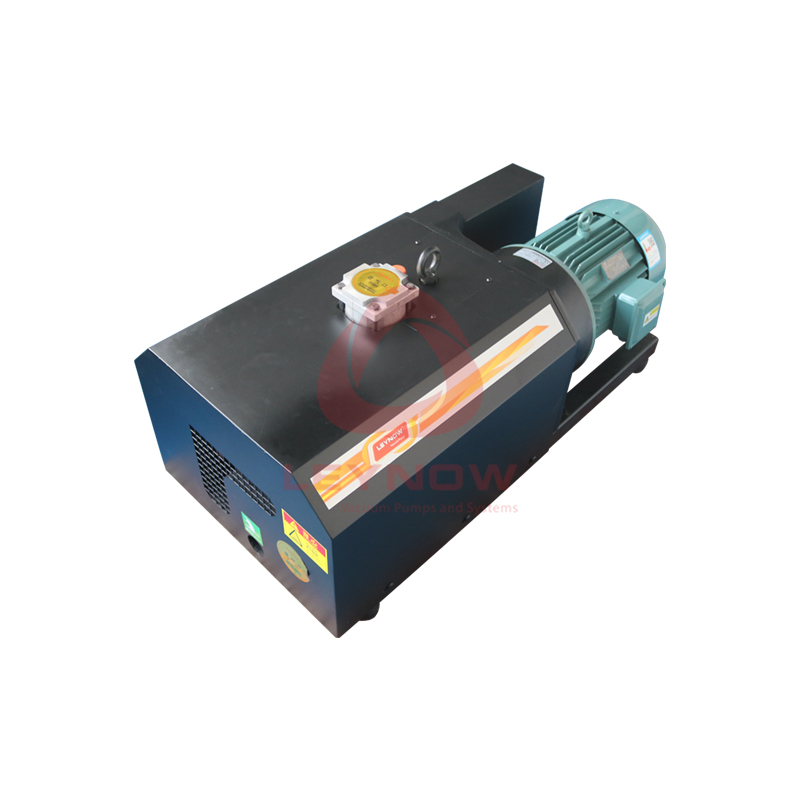

The market is driven by modern communication tools such as smartphones, tablets, TV flat panel displays or the Internet of Things. Whether it is an ion implanter, etching or PECVD equipment - LeyNow will find you a high-quality and high-reliability vacuum solution for optimal performance.

Semiconductor processing

The market is driven by modern communication tools such as smartphones, tablets, TV flat panel displays or the Internet of Things. Whether it is an ion implanter, etching or PECVD equipment - LeyNow will find you a high-quality and high-reliability vacuum solution for optimal performance. We continue to innovate leading technology solutions that improve process uptime, throughput, throughput and safety certification, while striving to balance this by mitigating environmentally harmful emissions, extending product life and reducing ongoing service costs Often conflicting requirements for lower cost of ownership.

Lithography

Lithography, the patterning of wafers, is a critical step in the semiconductor manufacturing process. While traditional and even immersion lithography generally do not require a vacuum environment, extreme ultraviolet (EUV) lithography and electron beam lithography do require vacuum pumps. LEYNOW allows you to effectively handle both applications.

chemical vapor precipitation

Chemical vapor deposition (CVD) systems come in a variety of configurations for depositing many types of thin films. The process also operates at different pressure and flow regimes, many of which use fluorine-containing dry cleaning processes. All of these variables mean you need to consult with one of our applications engineers to select the appropriate pump and gas reduction system to maximize service intervals for our products and increase uptime for your process.

etching

Because many semiconductors have very fine feature sizes, etching processes are becoming increasingly complex. Additionally, the expansion of MEMS devices and 3D structures increasingly uses silicon etching processes for structures with high aspect ratios. Traditionally, etching processes can be grouped into silicon, oxide, and metal categories. With more hard mattes and high-k materials being used in today's devices, the lines between these categories have become very blurred. Certain materials used in today's equipment can resist evaporation during the etching process, resulting in deposition within the vacuum components. Today's manufacturing processes have indeed become more challenging than they were a few years ago. We closely monitor industry and process changes and keep pace with them through product innovation to achieve best-in-class performance.

Ion implantation

Ion implantation tools still play an important role in the front-end process. The vacuum challenges associated with ion implantation have not become easier over time, and we recognize the challenges faced when operating vacuum pumps in noisy electronic environments. We never settle for absolute minimum performance testing in compliance with established electromagnetic immunity testing standards. We know that pumps used on injection tools will require higher immunity and special design features to ensure that the high voltage section of the injection tool does not interfere with pump reliability.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN